Checking and Setting Pitch at the Sleeve

For checking and setting pitch at the sleeve, we recommend using the following methods, which are the same methods used at Concept2. Be sure to follow the appropriate method for the blade type you have. For simplifying the task, Concept2 sells an accessory Pitch Check, which provides a level work surface and includes the necessary blocks for pitching various blade types.

Pitching Fat2, Smoothie2, Big Blades and Macon Blades

This method applies to all blades made from the 2007 Smoothie2 mold and 1987 traditional hatchet blade mold, with or without the Vortex Edge.

- Clamp a piece of wood or steel to one end of a bench or other stable structure. This block should have an even top surface and must be at least as long as your blade is wide.

- Use a bubble level and shims to level the block, then secure it to the bench.

- Position a support block (“V” blocks are helpful here) to hold the handle end of the oar off the bench.

- Place the blade of the oar face side down on the block, with the short side corner of the blade extending one inch beyond the edge of level block. Note: The centerline of the oar must be perpendicular to the level block.

- Position your level on the wear surface of the sleeve. If the surface is level, then the oar has zero pitch. If the surface is not level, then raise one edge of the level until it shows level. This will show you how much sleeve material will have to be removed to correct the pitch to zero. You may fine-tune the pitch as much as one-half (0.5) degree by filing or scraping down the wear surface.

- Use an adjustable pitch level for checking oars with a designated pitch other than zero.

Oar must be level for pitching.

Pitching Method for Original Smoothie and Fat Blades

This method applies to all blades made from the 1996–2006 Smoothie mold (referred to as the Smoothie 1 mold), with or without the Vortex Edge. When measuring these blades, do not include the curved portion at the top of edge of the blade.

Oar must be level for pitching an oar.

Our standard procedure with blades from the Smoothie 1 mold was to ship them with the pitch set so the oar can be put into rigging that was set for a Big Blade, with no adjustment required.

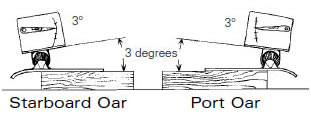

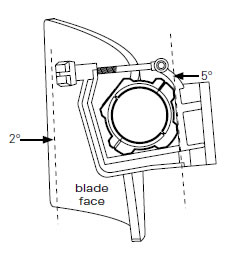

Blades from the Smoothie 1 mold perform best with the flat surface of the blade pitched at 2 degrees during the drive. With our standard oars, this surface will be set at -3 degrees relative to the sleeve/oarlock. Therefore, if you use this oar in an oarlock pitched at 5 degrees, the result at the blade face will be the desired 2 degree pitch:

5° − 3° = 2° net pitch at the blade face